Understanding the U.S. Distribution Landscape

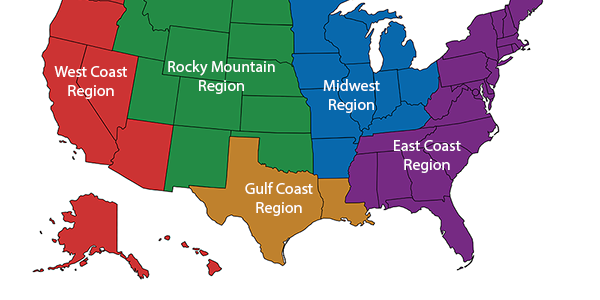

The U.S. spans a vast geographic area with varied consumer preferences across states and regions. Successfully distributing products within the country requires navigating these geographic and demographic factors. A well-structured distribution strategy helps businesses maximize reach and efficiency.

Regional Preferences and Market Demand

The U.S. market consists of multiple regions, each with unique preferences and market dynamics. For example, products that perform well on the East Coast may face different demand on the West Coast. Businesses should conduct regional research to understand demand in key markets and adapt their distribution strategy accordingly.

Demographic Analysis: Consider factors like age, income, and lifestyle when determining where to distribute products. A data-driven approach helps identify the best regions for launch and expansion.

Supply and Demand Variations: Regional preferences and seasonal demands impact product popularity. By aligning distribution with these trends, businesses can improve sales while avoiding overstock or shortages in particular areas.

Selecting the Right Distribution Channels

Choosing the right distribution channels is critical to reaching target customers effectively. Each channel has its strengths and challenges, and the right choice depends on the business model, product type, and target audience.

Direct-to-Consumer (D2C) Distribution

Direct-to-consumer (D2C) distribution allows businesses to sell directly to customers without intermediaries. This model is popular among brands looking to establish close connections with customers and control the purchasing experience.

E-commerce Platform: Many D2C businesses operate through e-commerce platforms, which provide an online storefront for customers nationwide. Platforms like Shopify, Amazon, and WooCommerce enable brands to sell products across the U.S. with minimal overhead costs.

Warehouse Fulfillment: For efficient D2C distribution, having a warehouse or fulfillment center that can handle orders and ship them quickly is essential. Partnering with a reliable fulfillment service helps businesses maintain customer satisfaction with timely deliveries.

Retail Partnerships

Retail partnerships offer businesses access to customers through physical stores and established distribution networks. Large retailers like Walmart, Target, and Costco provide nationwide reach, making it easier to distribute products widely.

Retailer Negotiations: To secure retail partnerships, businesses must understand retailer requirements, including product pricing, packaging standards, and vendor agreements. A clear value proposition helps during negotiations with major retailers.

In-Store Promotions: Working with retailers allows brands to run in-store promotions, which can increase brand visibility and boost sales. Coordinating with retail partners on promotions and displays enhances the product’s appeal to in-store shoppers.

Wholesaling and Distributor Partnerships

For brands looking to scale quickly, wholesaling and partnering with distributors are effective options. Distributors manage product storage, transport, and delivery, making it easier for brands to reach retailers and specialty stores.

Finding the Right Distributor: A distributor should have experience in the brand’s industry and a network that aligns with target customers. Conducting thorough research and vetting potential distributors ensures compatibility and service reliability.

Negotiating Distribution Terms: Clear communication about pricing, inventory requirements, and delivery schedules ensures a smooth partnership with distributors. A detailed contract covering terms and expectations prevents misunderstandings and protects the business.

Optimizing Logistics and Inventory Management

Efficient logistics and inventory management are critical to successful distribution within the U.S. By optimizing these aspects, businesses can reduce costs, avoid stockouts, and improve customer satisfaction.

Choosing Warehouse Locations

Warehouse locations significantly impact shipping costs and delivery times. Strategically positioned warehouses can speed up deliveries, particularly for businesses serving a national market. Many businesses use a network of warehouses across key regions to reduce shipping times.

Regional Fulfillment Centers: Establishing regional fulfillment centers in major hubs, such as Los Angeles, Chicago, and New York, can reduce shipping costs and improve delivery speeds for customers.

3PL Partnerships: Third-party logistics (3PL) providers offer storage, fulfillment, and distribution services, allowing businesses to scale operations without building an internal distribution network. 3PLs provide flexibility and can handle fluctuations in demand effectively.

Managing Inventory Levels

Balancing supply and demand is crucial for distribution efficiency. Inventory management systems help businesses track stock levels and anticipate demand, reducing the risk of stockouts or overstocking.

Demand Forecasting: Using data-driven demand forecasting allows businesses to predict sales patterns and adjust inventory levels. Accurate forecasts reduce waste and ensure products are available when needed.

Automated Inventory Management: Automated systems track inventory across warehouses, streamlining reordering processes and reducing errors. By integrating inventory management software, businesses can monitor stock levels in real-time and maintain efficient operations.

Navigating Legal and Compliance Requirements

Distributing products in the U.S. requires compliance with various federal, state, and local regulations. Non-compliance can lead to delays, fines, and reputational damage, so businesses must understand and follow all applicable regulations.

Product Labeling and Packaging Compliance

The U.S. has strict regulations for product labeling and packaging, especially in industries like food, cosmetics, and consumer goods. Businesses must ensure that labels meet the standards set by organizations such as the Food and Drug Administration (FDA) and the Federal Trade Commission (FTC).

FDA Regulations for Food and Drugs: The FDA regulates product safety and labeling for food, beverages, and cosmetics. Labels must include ingredients, nutritional information, and allergen warnings, ensuring transparency and consumer safety.

FTC Guidelines for Marketing Claims: Marketing claims must be truthful and substantiated. Statements like “organic,” “non-GMO,” and “made in the USA” are regulated, and misleading claims can lead to fines or recalls.

State-Level Compliance

Each state may have additional regulations that impact distribution. Businesses must be aware of state laws regarding packaging, recycling, and environmental impact.

State Recycling Requirements: Some states require certain materials to be recyclable or include recycling instructions on packaging. Compliance with state recycling regulations promotes sustainability and reduces potential fines.

Product Registration and Licensing: Certain products require state registration, especially if they’re regulated at the state level. Business consultants or legal experts can provide guidance on state-specific requirements to ensure smooth distribution.

Leveraging Technology for Distribution Efficiency

Technology plays an essential role in managing distribution networks and optimizing operations. Using digital tools for tracking, communication, and automation can help businesses streamline distribution processes and reduce costs.

Warehouse Management Systems (WMS)

A Warehouse Management System (WMS) helps businesses monitor inventory, track shipments, and manage storage. A WMS improves accuracy, reduces errors, and enhances efficiency, particularly for businesses with multiple distribution centers.

Inventory Tracking and Reporting: WMS platforms provide real-time data on stock levels, enabling businesses to anticipate inventory needs and prevent stockouts. By tracking inventory across warehouses, businesses can allocate resources more effectively.

Streamlined Fulfillment Processes: A WMS can automate order fulfillment processes, reducing the time needed to pick, pack, and ship products. Automation minimizes errors and speeds up the order processing, enhancing customer satisfaction.

Transportation Management Systems (TMS)

Transportation Management Systems (TMS) optimize shipping routes, track deliveries, and reduce transportation costs. A TMS integrates with carriers to select the most cost-effective and timely routes, improving delivery efficiency.

Route Optimization: TMS platforms use algorithms to find the best delivery routes, reducing fuel consumption and transit times. Route optimization is particularly beneficial for businesses with a large volume of deliveries.

Real-Time Shipment Tracking: A TMS provides real-time tracking, allowing businesses to monitor shipments and notify customers about delivery progress. This transparency builds trust and improves the customer experience.

Building Resilient Distribution Networks

Disruptions in distribution can arise from unexpected events, such as supply chain delays, natural disasters, or regulatory changes. Building a resilient distribution network prepares businesses to handle challenges effectively and maintain service continuity.

Diversifying Supplier and Distribution Channels

Relying on a single supplier or distribution channel increases vulnerability to disruptions. Diversifying suppliers and distribution channels allows businesses to adapt quickly if one channel becomes unavailable.

Multiple Fulfillment Partners: Working with several fulfillment partners offers flexibility and ensures continuity if one partner experiences issues. Multiple partners can also improve regional reach and delivery speed.

Alternative Shipping Options: In case of carrier delays, businesses should have alternative shipping options ready. Working with multiple carriers provides more flexibility and allows businesses to maintain delivery timelines.

Developing a Contingency Plan

Having a contingency plan reduces downtime and helps businesses respond effectively to unforeseen challenges. A well-thought-out plan includes alternative suppliers, inventory reserves, and protocols for managing communication during disruptions.

Emergency Stock: Maintaining extra stock of high-demand products reduces the risk of stockouts in case of delays. Emergency stock levels should be determined based on historical data and demand forecasts.

Crisis Communication Strategy: Transparency is essential during disruptions. A crisis communication plan that informs customers and stakeholders builds trust and helps maintain positive relationships during challenging times.

Key Takeaways for Effective U.S. Product Distribution

Distributing products within the U.S. requires a thorough understanding of regional dynamics, compliance requirements, and logistical efficiency. By selecting the right distribution channels, optimizing logistics, and leveraging technology, businesses can create a distribution strategy that supports growth and customer satisfaction.

Working with reliable partners, staying adaptable, and using data-driven insights improve distribution outcomes. With the right approach, businesses can effectively reach U.S. consumers, maximize market penetration, and build a strong presence in one of the world’s largest consumer markets. Here are the essential strategies for success when it comes to distributing products within the United States.